In an industry where every second and centimeter counts, the partnership between Lightbug, Swift Navigation, and Quectel is redefining what’s possible for lone worker safety. We sat down with Chris Guest, Founder & CEO of Lightbug, to discuss the market’s evolution, the unique technical challenges his team has solved, and how high-precision RTK is becoming an essential tool for protecting human lives.

SL: What was the driving force that led Lightbug to target the lone worker safety market?

CG: It was a mix of market “pull” and technical timing. Historically, our specialty was high-value asset tracking where long battery life and reliability were key. But in 2019, our partner Onwave brought us a challenge from Network Rail, who had put out a tender for worker safety. They needed a solution that could prove a concept worked within a very tight three-to-six-month window. We successfully developed a prototype using 3D-printed plastics and early modules, and the rest is history.

We soon realized that as component costs and power consumption for RTK (Real-Time Kinematic) technology dropped, we were on the cusp of it being feasible for wearable safety applications. Historically, RTK was an exclusive, pricey tool for surveying. We saw a growing market where this precision could be moved from assets to people.

SL: How is the lone worker safety market evolving, and what trends should key players be watching?

CG: The primary trend is the shift from just providing safety to automating safety. Major infrastructure companies have done a fantastic job of getting close to zero incidents through training, but that last remaining gap is almost always down to human error. High-precision technology is now enabling a new standard of safety that will likely become a mandatory requirement for big infrastructure projects in the coming years.

We’re seeing three major pillars of evolution:

- Efficiency and Productivity: Safety isn’t just a cost; it’s an efficiency play. For example, a 15-minute safety briefing for a two-hour shift is standard. If you can automate the alerting system and reduce the scope of those briefings, you gain roughly 12% in productivity.

- Dynamic and “Just-in-Time” Work: We operate in a reactive world. Work sites are no longer fixed; they change daily. High-precision tracking allows for a ‘bird’s-eye view’ to manage these fluid sites, allowing a single team to be used for many different dynamic applications safely.

- The AI Link: With the rise of AI, we expect to see massive process automation in how work is assigned. However, AI needs a reliable link between the digital and physical worlds to function. Accurate, high-precision location data is the essential prerequisite for AI-driven workforce optimization.

SL: Lightbug is an internationally successful company, are there differences in how worker safety is addressed across countries? What country-specific challenges have you encountered, and how have you approached them?

CG: We split this into two parts: technical and cultural/business.

- Technical: This involves dealing with different compliance requirements and network variations, which is a fairly well-understood baseline challenge.

- Cultural/Business: This varies hugely based on industry, country, and culture. The key factors that repeat themselves are privacy, data security, and data sovereignty. We navigate this by being open, allowing people to control their own data, and using encryption to fit within their compliance regimes.

We also see differences in adoption willingness. Japan and various other Asian countries have really pushed for automation and have a high focus on health and safety, making them leaders in this space. The UK is not far behind, followed closely by Europe, and then the US. There are also organizations that use this technology not just for safety, but for monitoring worker productivity and assigning tasks, which can be challenging in different regulatory environments.

SL: What is the unique value proposition of Lightbug’s advanced solution compared to its competitors?

CG: There aren’t a huge number of competitors in the high-precision personnel safety space. When comparing ourselves to the general market of standard GPS devices and mobile safety apps, our key USP is accuracy and reliability. Standard GPS trackers often only offer about 65% confidence, which is not enough for serious safety automation.

If we compare ourselves to the handful of other companies doing RTK safety devices, our edge is size, battery life, and affordability. We’ve figured out how to make RTK devices last several days on a single charge, which is a massive operational win. You don’t have to recharge every shift. Furthermore, because of our partnerships, we’ve brought the cost down to a point where it’s feasible to deploy across a workforce of 40,000 people. It’s no longer a “thousand-dollar-per-worker” investment; it’s becoming closer in affordability to standard GNSS.

SL: Lightbug has recently focused on leveraging Swift Navigation's Skylark™ Precise Positioning Service. What specific problem were you looking to solve by integrating this technology, and what does it unlock for your clients that standard GPS cannot offer in the context of lone worker safety?

CG: RTK correction data is night and day compared to standard GPS. If you want to take safety seriously, you need centimeter-level accuracy that is consistent across a wide geography. Historically, we managed our own base stations. It works for a single site, but it doesn’t scale. You end up spending a huge amount of time setting up stations, managing them, and troubleshooting why accuracy is dropping in a specific corner of a project.

By using Skylark, we get a single source of truth that just works. For our large, distributed infrastructure clients, being able to offer high-precision positioning across multiple regions in a standardized way is a huge benefit. Swift provides the Service Level Agreements (SLAs) and reliability we need to pass on to our customers, both in terms of positioning accuracy and alerting reliability. It massively reduces failures during pilots and testing because we aren’t worrying about the correction data—we can focus on the safety logic.

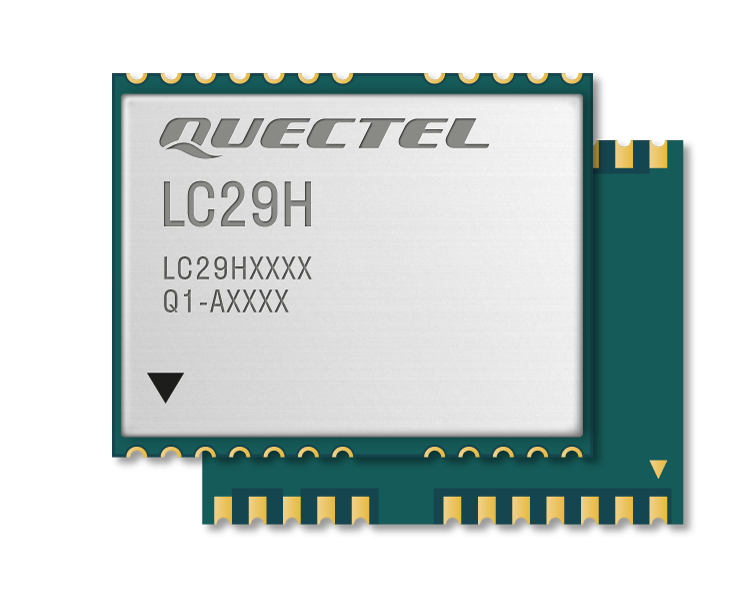

SL: With the wide array of GNSS modules on the market, what made you decide to go with Quectel’s LC29?

CG: While we were very impressed by the performance of the Airoha AG3335 chipset, we ultimately selected the Quectel module to take full advantage of their specialized positioning engine. Quectel’s unique integration with the Airoha hardware provided the specific optimization our project required. When you’re dealing with safety, that engine’s ability to handle data and provide a reliable fix is everything.

The price point was great, and the reliability, accuracy, and general value were far better. The LC29 series also offers a nice range of modules, some with dead reckoning built in, with various levels of performance and pricing. Because they share the same electronic PCB footprint, we have the flexibility to offer our customers different levels of performance and pricing without having to redesign our hardware from scratch. That versatility is a huge benefit for us as we scale into different industries.

SL: What are the advantages of the pretested solution from Lightbug, Swift and Quectel?

CG: What people are buying into with this integrated tech stack is years of experience. RTK has been around for over 20 years, but it is very difficult to get right, especially because of the stringent accuracy requirements in challenging edge case scenarios like urban canyons and tree cover.

The Lightbug-Swift-Quectel partnership offers a pre-tested, pre-validated solution which is a massive head start for our clients.

- Focus on Business Logic: It enables people to focus on the business logic, actually using the technology for safety, rather than worrying about the underlying technology.

- Reliability: The biggest issue in IoT is the edge cases. If a system only works 80% to 90% of the time, that’s not good enough, especially for safety. By leveraging things that have already been done by experts in their respective fields, companies gain a level of reliability that means they don’t have to reinvent the wheel, ensuring the system works not just most of the time, but when it matters most.

SL: Lone workers often operate near large structures, deep within urban canyons, or under heavy tree canopy. These conditions are notorious for causing GNSS multipath and signal dropouts. How does Lightbug ensure that its devices maintain centimeter-level accuracy in these challenging environments?

CG: This is the single biggest challenge in this use case because perfect line-of-sight to the sky is very rare on a construction site or railway, for example. We’ve had to optimize every layer of the hardware to deal with this, and combine it with intelligent software.

- Hardware & Antenna: We selected a helical antenna because it is designed to be close to a human body, doesn’t detune easily, and provides very good multipath mitigation. We also leverage Quectel’s module with L1/L5 signals, where the slightly stronger L5 signal helps in challenging conditions.

- Intelligent Fallbacks: Even with the best hardware, a 100% guarantee is impossible. A lot of our work has gone into gradual fallbacks in functionality. If a device drops from 1 cm accuracy down to 1 meter, the software will automatically adjust the alerting system to increase the margin of safety by 1 meter. This ensures that we are always providing the highest possible level of safety while dealing with varying qualities of GNSS fixes.

SL: How does your geofencing capability, through your partnership with Onwave, contribute to lone worker safety in practice?

CG: As with all technology, our devices don’t exist in a vacuum. Real people in real world scenarios need to integrate it into their day-to-day operations. This is where the geofencing comes in: Onwave’s platform allows for rapid set up of work zones and tagging of hazards. Taking Network rail as an example, Onwave’s platform can take rail track data and automatically generate base zones for a project. Physical safety assets such as marker boards are tagged to enable a very accurate “digital twin” of a worksite. This eliminates the need for safety managers to spend hours manually clicking around on a map.

In practice, this creates a “digital twin” of the worksite. We can reduce near-misses by alerting a worker the second they step onto the wrong side of a track—turning a potentially fatal mistake into a simple, handled alert. On track staff can alert the system that they are using dangerous equipment, which can then automatically warn nearby users of a hazard if they get within a certain perimeter. It also allows for dynamic hazard tracking. If a track cleaner is moving through a site kicking up dangerous gravel, the asset itself acts as a moving geofence. Anyone standing near it gets an alert that a hazard is approaching from behind, even if they aren’t moving.

SL: What misconceptions do organisations typically have about high-precision location systems before working with Lightbug?

CG: There are two big ones. First, many people simply don’t believe that centimeter accuracy is achievable in a small, wearable tracker. They are so used to the limitations of standard GPS that educating them on what is now possible is probably our biggest job. They’ve often tried mobile apps or basic trackers and found them wanting, so they assume the technology just isn’t there yet.

The second is cost and infrastructure. Historically, if you wanted high precision, you looked at systems like UWB (Ultra-Wideband), which required massive infrastructure investment – installing anchors all over a site. Organizations expect a system to cost thousands per worker plus huge monthly fees. We are proving to the market that you can get survey-grade accuracy in small devices, with zero site infrastructure and at a price point that actually scales for a workforce of tens of thousands.

SL: What are some real-world examples of your devices being put to use to protect lone workers?

CG: Our work with Network Rail and the Onwave geofencing platform is a prime example.

- Protecting Track Workers: When work is conducted on the tracks, they are allocated a specific area, or ‘possession.’ Historically, the limitations were marked by physical marker boards, which are easy to miss when you are busy. We have been able to reduce near-misses where a worker was close to walking onto the wrong side of the track. The system alerts them just before, turning a near-miss into a handled alert.

- Dynamic Hazard Zones: On work sites, machinery like track cleaners kick up huge amounts of gravel and are dynamically dangerous. By tracking the location of this moving asset and tying that in dynamically to the alerting system, we ensure that even a worker standing still will get an alert saying, “You have a hazard approaching behind you.”

- Welders/Hand Tools: Workers can manually input that they are using a dangerous hand tool (like a welding torch or chainsaw) into the Onwave system, and all nearby workers are automatically alerted, creating a temporary digital safety zone around the active hazard.

Already scaling worker safety deployments or looking to integrate high-precision GNSS into your own hardware? Sarah is available at [email protected] to discuss tailored positioning solutions and explore strategic partnership opportunities. Learn more about Swift Navigation’s Skylark™ Nx RTK and how our ecosystem approach can power your safety deployments and product integrations.

Ready to evaluate Skylark? Head over to MikroE to pick up the GNSS RTK 3 Click Board. Built on the Quectel LC29H platform, it comes bundled with 6 months of free Skylark RTK corrections.